Tire Pressure

by Andy Boyd

Today, under pressure. The University of Houston's College of Engineering presents this series about the machines that make our civilization run, and the people whose ingenuity created them.

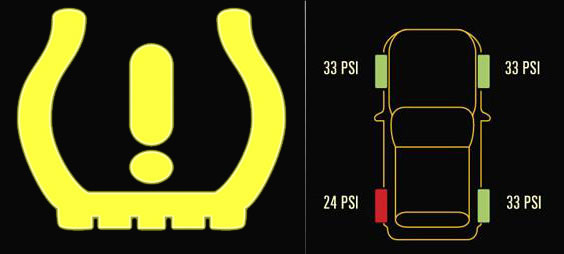

Car dashboards can at times seem overwhelming: gauges, climate control systems, radios. And all those pesky warning lights, including the congressionally mandated low tire light.

The late nineties saw a rash of highway fatalities when Firestone tires failed on Ford Explorers. Congress responded by passing the TREAD Act, a provision of which required all new cars to include tire pressure monitoring systems. Full compliance was achieved by 2008.

So how's pressure actually measured while a car's moving? Wires can't be run to a spinning tire like other parts of a car. That leaves an interesting engineering challenge.

Two basic methods are used. The earliest methods, known as indirect, don't actually measure tire pressure, they infer it. The most common indirect method tracks the rotation of the wheels. If one wheel is rotating faster than the others, it has a smaller radius, implying it's flat — or, at least, low on air. The method isn't the most accurate, but it has one big advantage: it doesn't require any major new car parts — just changes to a car's computer programs. Research continues on ways to improve indirect methods.

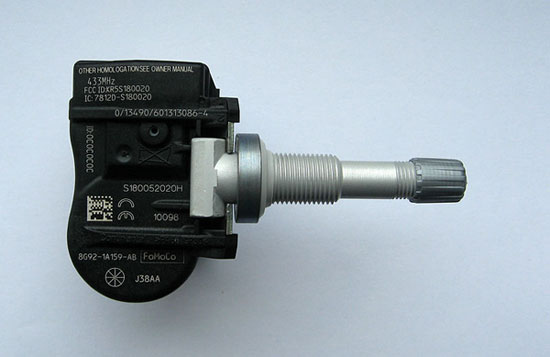

The alternative, direct methods, actually measure the tire pressure. A pressure sensor is placed inside each tire, usually attached to the valve stem. Each sensor comes equipped with its own battery, and pressure information is radioed to the car.

Direct methods are pretty accurate, but have their drawbacks. The cost of a sensor starts at around fifteen dollars. When a sensor's battery goes out it needs to be replaced, which requires removing the tire. Sensors are mechanical devices in a harsh environment. Some will inevitably fail. Here again, research to better overcome these obstacles is ongoing.

Common to all pressure monitoring systems is the warning light found on a car's dashboard. If a tire's pressure is low, the light will stay on until the problem's fixed. Since tires tend to deflate a bit over time, we'll be seeing a lot more people at the air pumps — people who may be dismayed by the inconvenience.

So what do we really gain from tire pressure monitoring systems? For one, fewer traffic fatalities. Improperly inflated tires can lead to blow-outs or tread separation, either of which can be catastrophic at highway speeds. In addition, cars get better gas mileage when tires are properly inflated. If you've ever ridden a bicycle with low tires, you know it takes more energy to pedal.

Do the advantages outweigh the cost and inconvenience? It depends on who you talk to. But like it or not, tire pressure monitoring systems are with us to stay.

[Music: David Bowie's Under Pressure]

I'm Andy Boyd at the University of Houston, where we're interested in the way inventive minds work.

Notes and references:

T. Nash. 'Keeping an Eye on PSI: Tire Pressure Monitoring Systems, Part I.' From the AutoInc. Online Edition Web site: http://www.autoinc.org/archives/2008/jan2008/mech.htm. Posted January 8, 2008. Accessed November 1, 2011.

The pictures of the approved warning lights are from the safecar.gov Web site of the U.S. Government. The picture of the tire pressure sensor and valve is from Wikimedia Commons.

This episode was first aired on November 17, 2011