Automobile Drag Coefficients

Today, aerodynamics and automobiles. The University of Houston's College of Engineering presents this series about the machines that make our civilization run, and the people whose ingenuity created them.

The first cars were made before the Wright brothers flew and before they'd even started doing wind tunnel tests. Wind tunnels were used in airplane design from the start. Car designers were far slower to see that aerodynamics also affected their work.

At the turn of the twentieth century, Germany set up a number of high-level technical universities, which put them way ahead in aerodynamic research. In 1921, it was the Zeppelin Airship Works that first studied automobile streamlining in wind tunnels.

Automobile drag can be a serious gas-eater. When I was a kid, I entertained myself on long auto trips by putting my hand out the window and turning it at various angles to the wind. The forces, even on a child's small hand, were quite strong. And small changes in the shape and orientation of my hand made huge differences.

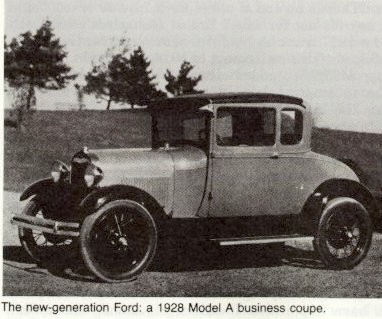

The usual measure of aerodynamic efficiency is the drag coefficient, CD. It compares the drag force, at any speed, with the force it'd take to stop all the air in front of the car. Drag coefficients for the first boxy autos were up over 0.7. Instead of letting the air slip past, they brought most of it to a halt.

In most of today's cars that figure is down to a scant 0.3. Of course there's more to it than just lowering the drag. It's easy enough to reduce drag if we let ourselves create other aerodynamic problems when we do. A car has to be designed for negative lift. The wind should press it solidly down against the road. And cars must not be vulnerable to crosswinds.

As early as 1907, a streamlined racing car called the Rocket reached 132 miles per hour before it became airborne. It had a low drag coefficient, but it was still a bad aerodynamic design.

Streamlining was the new design icon in the 1930s, yet that was more an illusion of speed than real drag reduction. Only a few cars had been wind-tunnel tested. The famous Chrysler Airflow was the exception, with far less drag than most of the cars following it.

It took time for engineers to see that they had to smooth the bottom of an automobile as much as the top. It took time to see that sharp corners on the front of a car were terrible drag-inducers. Only in the last generation did 18-wheelers sprout those strange-but-effective, drag-reducing cowls over their cabs. And only since WW-II has wind tunnel testing been a regular part of car design. Only recently has accurate computer simulation let engineers use rapid trial and error to improve aerodynamic designs.

That's why today's cars offer so little drag. And of course they're looking more and more alike. As designers work with increasing knowledge of design limitations, they close in on optimal designs that cannot vary much from one car to the next. It's just because our cars are such fine machines that we no longer look at the wild sunspray of possibilities -- which got us to where we are.

I'm John Lienhard, at the University of Houston, where we're interested in the way inventive minds work.

(Theme music)

Flink, J. J., The Path of Least Resistance. American Heritage of Invention & Technology, Fall, 1989, pp. 34-44.

The 1928 Model-A Ford still showing no concessions whatever to good aerodynamics