Screw Caps for Wine

by Andrew Boyd

Today, a turn of the screw. The University of Houston's College of Engineering presents this series about the machines that make our civilization run, and the people, whose ingenuity created them.

A friend recently came to me with the following story. He'd taken an important client to dinner where he ordered wine — not the most expensive on the list, but certainly not the cheapest, either. To his horror, it arrived with … a screw top. That meant no waiter ceremoniously fussing with a corkscrew. No satisfying pop. No cork to examine. Just a quick twist of the wrist and a slight metallic "click" as the seal was broken. The waiter, who you can imagine had dealt with this situation before, said some of the finest wines in the world were bottled with screw tops. My friend wasn't so sure.

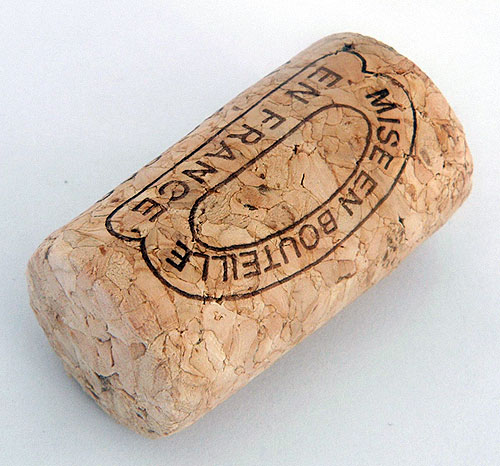

The primary purpose of a bottle stopper is to keep the wine in the bottle. Wine was made long before the invention of the metal screw cap, and the bark of the cork tree was an ingenious engineering solution. Cork can be compressed, placed in the neck of a bottle, and when let go, it expands to form a nice, tight seal. Simple and elegant.

But corks can become infected with mold, which in turn can affect a wine's flavor. Evidence suggests that about five percent of wine bottles sealed with cork will become tainted. Metal screw caps don't have the same problem.

Many wine enthusiasts have embraced metal caps. Others point out that corks breathe, allowing air to pass between the inside and outside of a bottle. They argue that's important for a wine's flavor, especially a wine that's aged over many years.

Not everyone agrees about the importance of a breathing stopper. But it is true that as wines age, naturally occurring sulfides degrade and produce a sulfurous odor. Exposure to oxygen neutralizes the smell. In most cases, the air in the bottle is good enough to do the job. But if not, a freshly unscrewed bottle can, in the words of one industry expert, "smell like a stink bomb." It's actually an easy problem to fix — just let the wine air out a bit. But that would certainly pose a problem for waiters in fine restaurants.

Of course, there is another solution, and screw top makers are already on top of it: manufacture screw tops that breathe. Metal caps aren't all metal. They have composite plastic liners where the bottle meets the cap. These liners can be carefully engineered to allow desired levels of oxygen to pass through. A winemaker can actually choose how much air he wants to let in and out of the bottle.

So the screw top bottle is capable of handling the world's finest wines. The problem, of course, is in the presentation. Over the years, we've come to associate screw tops with cheap, unpleasant wine. And twisting really is a different experience than popping. Can engineering supplant centuries of tradition? That remains to be seen.

I'm Andy Boyd at the University of Houston, where we're interested in the way inventive minds work.

Notes and references:

Experts Raise a Stink Over Screw-Top Wine Bottles. The Daily Mail, January 15, 2007. See also the Daily Mail Web site: http://www.dailymail.co.uk/news/article-429023/Experts-raise-stink-screw-wine-bottles.html. Accessed February 2, 2010.

B. Giliberti. Screw Tops: Get Used to Them. The Washington Post, October 13, 2004 p. F7. See also the Washington Post Web site: http://www.washingtonpost.com/wp-dyn/articles/A26966-2004Oct12.html. Accessed February 2, 2010.

M. Johnson. Meanwhile: Learning to Love the Screwtop Wine Bottle. New York Times, April 18, 2007. See also the New York Times Web site: http://www.nytimes.com/2007/04/18/opinion/18iht-edjohnson.1.5333412.html. Accessed February 2, 2010.

Why Choose the Stelvin Concept? From the Alcan Web site: http://www.stelvin.com/why-choose-the-stelvin-concept_en.html. Accessed February 2, 2010.

The picture of the cork is taken from Wikimedia Commons. The pictures of the screw top bottles and of the liners used in Alcan's Stelvin screw tops are from the Alcan Web site. Stelvin is a registered trademark of Alcan.