y the time Marcet's later editions were appearing, they were no longer being hand-made by young apprentices. Nor were they being aimed only at young ladies, then barred from Universities. Now they were pouring forth from a new generation of fast rotary presses, and they were being read by boys and girls alike, in schools and outside them.

y the time Marcet's later editions were appearing, they were no longer being hand-made by young apprentices. Nor were they being aimed only at young ladies, then barred from Universities. Now they were pouring forth from a new generation of fast rotary presses, and they were being read by boys and girls alike, in schools and outside them.

To better see how that had taken place, I find it useful to close my eyes and remember those times I've watched large newspaper presses at work. Huge rolls of paper, weighing over a ton, feed a machine that stretches far across the print room floor. Paper moves far faster than the eye can follow, as the press prints, cuts, and folds it. Those immense machines touch something beyond mere sight and sound.

Compare that with a hand press that allowed two printers to finish a few hundred sheets a day. Then the magnitude of the 19th-century printing transformation is clearer. Printers still used wooden hand presses during the 18th-century Industrial Revolution. Only after that did bookmaking begin to change. Inventors began building heavier, more stable frames. They began adding clever mechanisms to speed the printers' output.

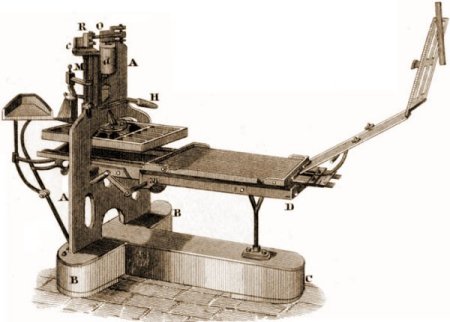

And then, around 1800, the Earl of Stanhope changed the game. He built an all-metal press in which the operator used compound levers to drive a conventional screw mechanism. It imposed an increasing pressure that was highest right at the end of the printing stroke. Printers who once had to impress each half of one side of the paper separately could now, with far less effort, print a whole sheet in one pull of their lever.

A Stanhope Press

The Stanhope press went through a variety of improvements, and soon spawned more advanced all-metal designs. One of the notable ones was the American Columbian press, created by George Clymer in Philadelphia during the War of 1812. It was lighter than Stanhope's, and it included a major conceptual leap. Clymer eliminated the old Gutenberg screw drive entirely. He used a highly sophisticated three-dimensional system of levers to magnify the force of the printer's arm. From then on, it would be he, not Stanhope, whom others would build upon when they tried to improve the hand press.

Clymer's Columbian press

The chief advantage of these new iron presses was that they made it easier to produce high-quality printed matter. They still had to print one sheet at a time, just as they had to do on the old wooden presses. But they provided a far more stable platform on which to add other features – means for loading the next sheet of paper, and re-inking the type, more quickly.

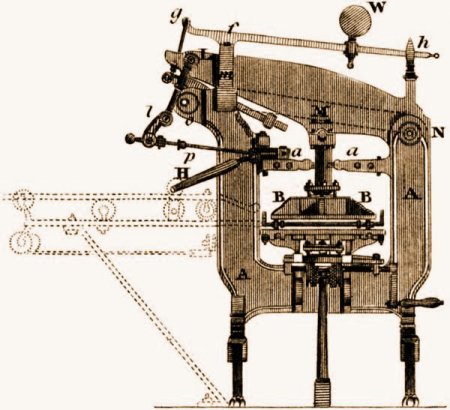

When we visualize that huge newspaper press, even these now souped-up hand presses seem intolerably slow. They would clearly have to give way to some means for printing a steady flow of paper as it moved through some form of rollers. The idea of a roller press was floated by several inventors during the 18th century, and several people tried to carry off the complex task of building one.

Complexity is precisely what delayed such a machine until the 19th century. German inventor Friedrich Koenig finally had an embryonic, steam-powered, working roller press in 1811. That was followed by several improvements, including a solution to the fiendishly complex problem of printing on both sides of the paper. Think about that for a moment; just imagine the difficulty of doing two separate printings, front and back, on a moving sheet of paper, and placing each accurately on the sheet.

Above: a Koenig double roller press, manufactured by Applegath and Cowper in London before 1827; below: the inking scheme, and the movement of paper, in this press.

But Koenig was still printing single sheets of paper. A variation on the roller press, developed later in the 19th century, was the so-called web-fed press. That was the machine, fed by huge rolls of paper, that we paused to watch a moment ago.

By the late 1820s those complex cylinder machines were major providers of printed matter. The printed word could now reach the vast general public in ways that would really transform the world, along with the very texture of knowledge.

J. Moran, Printing Presses: History and Development from the Fifteenth Century to Modern Times. (Berkeley, CA: University of California Press, 1973): Chapters 3-5.

The Edinburgh Encyclop�dia (David Brewster, ed.) Vol. III (Philadelphia: Joseph and Edward Parker, 1832).

Cyclop�dia of Useful Arts, Mechanical and Chemical, Manufactures, Mining, and Engineering. (Charles Tomlinson, ed.) (New York: George Virtue & Co. 1854): pp. 487-490.