Downward Diffusion

Today, technology keeps diffusing downward. The University of Houston's College of Engineering presents this series about the machines that make our civilization run and about the people whose ingenuity created them.

Nineteen years ago I talked about a Science Magazine paper by Al Gore. He'd just become Vice President and it was long before is name was mired in really high-stakes political combat. I suspect he was languishing in the sort of Vice Presidential doldrums that John Nance Garner called a bucket of warm spit - that he'd simply reverted to his previous life as a technology journalist.

In any case, the paper was very perceptive. Gore talked about the downward diffusion of technology. And it's time revisit the idea that technologies begin large and centralized. Then they grow smaller and more intimately diffused among a population.

A classic example is the central factory power supply. A single steam power plant once drove a vast system of shafts and belts throughout a factory. With the coming of electricity, a single huge electric motor replaced the steam engine -- driving all those spinning shafts. It took us another 30 years to see that a factory is far more flexible with a small motor at each work station.

Same with computers: We clung to the belief that computing should all done on one huge main-frame machine. We doggedly held that conviction through the '60s and '70. Then, in the early '80s, we caught on and put personal computers on our own desks. At that point Earth shifted upon its axis. The results of that downward diffusion of technology far outran mere computation.

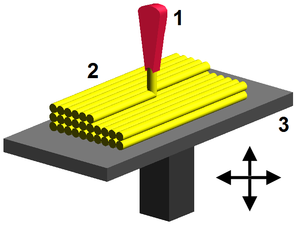

Now another technology rises up on the edge of our awareness. It's the 3D printer. The usual way to make complex parts is by casting -- pouring metal into a mold. Clearly some things can never be cast -- especially things with moving parts.

But now we can provide a 3D printer with a drawing of our new ball bearing or our crescent wrench. We then "print" the 3-D object by laying down very thin layers of some material. Each layer fuses onto the one below it leaving whatever gaps and spaces are needed. Out pops the finished item with parts moving inside one another. (I'll post some videos on our website. They are eerie to watch.)

But now we can provide a 3D printer with a drawing of our new ball bearing or our crescent wrench. We then "print" the 3-D object by laying down very thin layers of some material. Each layer fuses onto the one below it leaving whatever gaps and spaces are needed. Out pops the finished item with parts moving inside one another. (I'll post some videos on our website. They are eerie to watch.)

Magical as all this may seem it's just in its infancy. We have much to do in the way of creating stronger and tougher fusible materials. However, just think where this is all headed. Can you imagine a world where we print out, on our own desktop, things once made in China, shipped to the US and sold to us in stores?

Now we look toward local 3D printing of fabrics, electronic circuit boards, lenses, dental crowns, even body parts. All this comes upon us with such speed that it could be cold news by 2020.

Yet it's only one more example of technology's steady downward diffusion. Think how the automobile made transportation individual and reshaped cities. How the cell phone now takes the computer off the desk and puts it in our pockets. It leaves me wishing I could ask my great-grand-daughter where all this will have taken us.

I'm John Lienhard at the University of Houston, where we're interested in the way inventive minds work.

My original piece on downward diffusion was Episode 1114 and the Gore article was "The Metaphor of Distributed Intelligence". Science, Vol. 272, 12 April, 1996. See also Episode 1749.

Much 3D printing is called "rapid prototyping" -- a term I have not used in this episode. This technology has indeed found a useful role in prototyping designs. However it is also being increasingly used to provide finished items.

The Internet is burgeoning with articles on 3D printing and rapid prototyping. The Wikipedia article on 3D printing is a good place to start. And here are two YouTube videos showing the "printing" of a crescent wrench and of a ball bearing.

An Audi advanced automobile model produced by 3D printing. This and the image in the text are courtesy of Wikimedia Commons.

This episode was first aired on July 2, 2012